ZhongLian

- Author:

- Source:

- Date: 2023-04-24

- Views: 113Times

1. Scope*

1.1 This standard covers a test method for measurement of

thermal impedance and calculation of an apparent thermal

conductivity for thermally conductive electrical insulation

materials ranging from liquid compounds to hard solid mate

rials.

1.2 The term “thermal conductivity” applies only to homo

geneous materials. Thermally conductive electrical insulating

materials are usually heterogeneous and to avoid confusion this

test method uses “apparent thermal conductivity” for determin

ing thermal transmission properties of both homogeneous and

heterogeneous materials.

1.3 The values stated in SI units are to be regarded as

standard.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro

priate safety, health, and environmental practices and deter

mine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accor

dance with internationally recognized principles on standard

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:2

D374 Test Methods for Thickness of Solid Electrical Insu

lation (Metric) D0374_D0374M

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

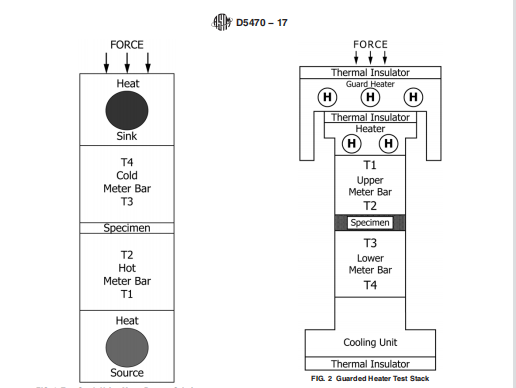

E1225 Test Method for Thermal Conductivity of Solids

Using the Guarded-Comparative-Longitudinal Heat Flow

Technique

3. Terminology

3.1 Defifinitions of Terms Specifific to This Standard:

3.1.1 apparent thermal conductivity (λ), n—the time rate of

heat flflow, under steady conditions, through unit area of a

heterogeneous material, per unit temperature gradient in the

direction perpendicular to the area.

3.1.2 average temperature (of a surface), n—the area

weighted mean temperature.

3.1.3 composite, n—a material made up of distinct parts

which contribute, either proportionally or synergistically, to the

properties of the combination.

3.1.4 homogeneous material, n—a material in which rel

evant properties are not a function of the position within the

material.

3.1.5 thermal impedance (θ), n—the total opposition that an

assembly (material, material interfaces) presents to the flflow of

heat.

3.1.6 thermal interfacial resistance (contact resistance),

n—the temperature difference required to produce a unit of heat

flflux at the contact planes between the specimen surfaces and

the hot and cold surfaces in contact with the specimen under

test. The symbol for contact resistance is RI .

3.1.7 thermal resistivity, n—the reciprocal of thermal con

ductivity. Under steady-state conditions, the temperature

gradient, in the direction perpendicular to the isothermal

surface per unit of heat flflux.

3.2 Symbols Used in This Standard:

3.2.1 λ = apparent thermal conductivity, W/m·K.

3.2.2 A = area of a specimen, m2 .

3.2.3 d = thickness of specimen, m.

3.2.4 Q = time rate of heat flflow, W or J/s.

3.2.5 q = heat flflux, or time rate of heat flflow per unit area,

W/m2 .

Copyright © Yiwu Zhonglian Technology Co,.Ltd

TEL:0755-26395762 386, Whatsapp: 86-13803526903

Add: Sufu Road, Suxi Town, Yiwu Industrial Park, Zhejiang Province.322000

网站建设维护